Thermal Interface Material (TIM)

ZEON Thermal Interface Material VB200

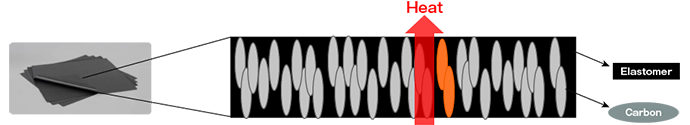

Zeon’s standard grade, VB200 is a sheet-type thermal interface material (TIM) developed based on a special elastomer designed to solve the thermal management issues associated with the miniaturization and high integration of electronic devices in recent years.

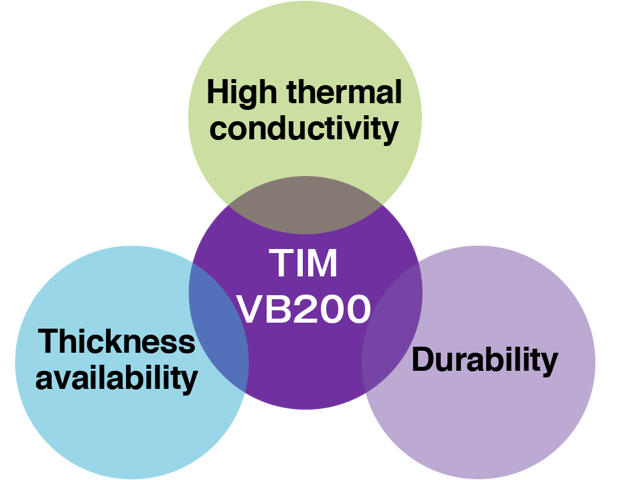

- High thermal conductivity

38W/m K*1in the thickness direction (Z axis)

- Thickness availability

Thin sheets available using special processing technology

- Long term durability

Suppresses degradation of thermal resistance during heat cycle testing

- *1 Not guaranteed as it is a measurement value

VB200 Typical applications

Typical applications

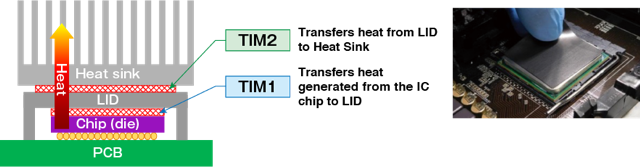

Fill gaps between heat-generating parts such as IC chips and heat-dissipating parts such as heat sinks, and efficiently transfer heat by taking advantage of high thermal conductivity.

Zeon’s TIM can be applied to both TIM 1 and 2 applications.

Basic Properties/Thermal Resistance Comparison

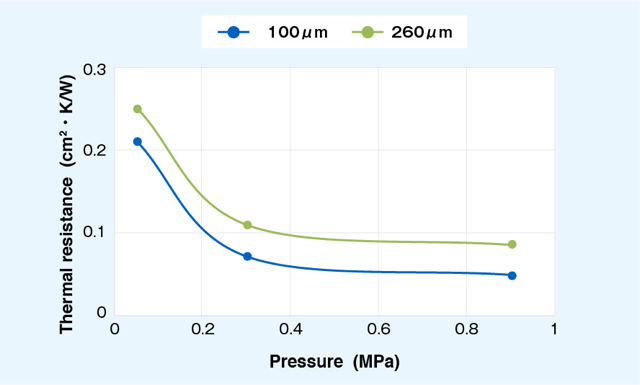

| Properties | Units | Value |

|---|---|---|

| Thickness | μm | 100~260*1 |

| Thermal conductivity (Z-direction) |

(W/m・K) | 38*2 |

| Compressibility | % | 11*3 |

| Flame retardance(UL94) | - | Equivalent to V-0 |

- *1For thicknesses outside this range, please contact us.

- *2This is a measured value and not guaranteed.

Those above data are measured values and not guaranteed values. - *3Measured under the following conditions:

Thickness 100µm, Temperature 50℃, Pressure 0.3MPa.

- *This is a measured value and not guaranteed.

- *The data above is the actual measurement data at Zeon based on ASTM D5470.

Durability Testing

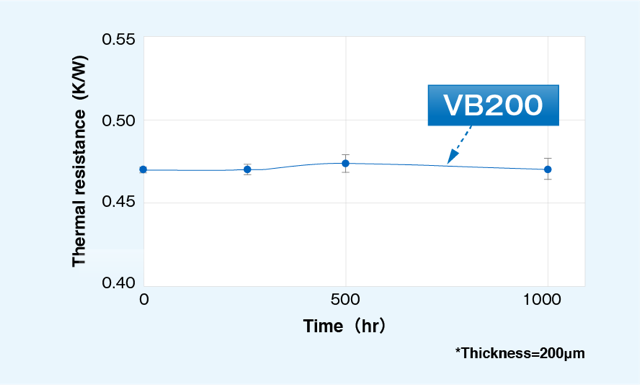

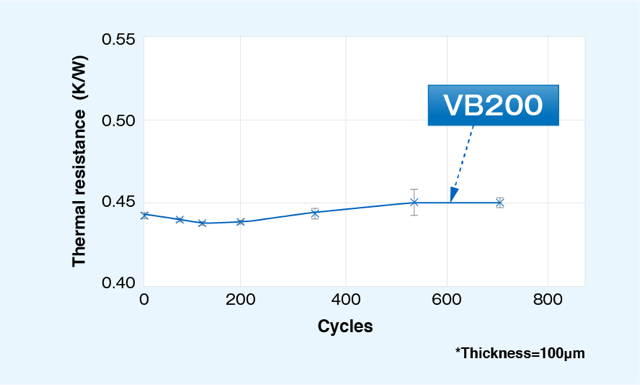

【High Temp. Long Term Storage and Heat Cycling】

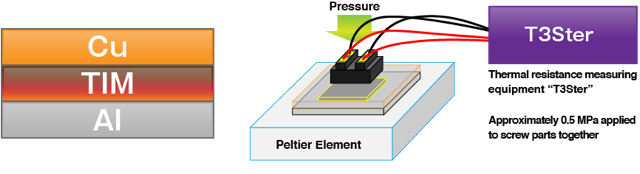

Method

- Form the structure above(Copper plate+TIM+aluminum plate) and conduct heat resistance and durability testing.

- Evaluate the thermal resistance of the structure.

| Process | Temperature [℃] | Time |

|---|---|---|

| Long term Heating | 150 | 1000hrs |

| Process | Temperature [℃] | Time |

|---|---|---|

| Cooling | -55 | 30 min. |

| Heating | 150 | 30 min. |

| Time per 1 cycle | 60 min. | |

Thermal performance maintains even after heat cycle testing and

long term high temperature exposure condition.

Durability Testing 【Reflow testing】

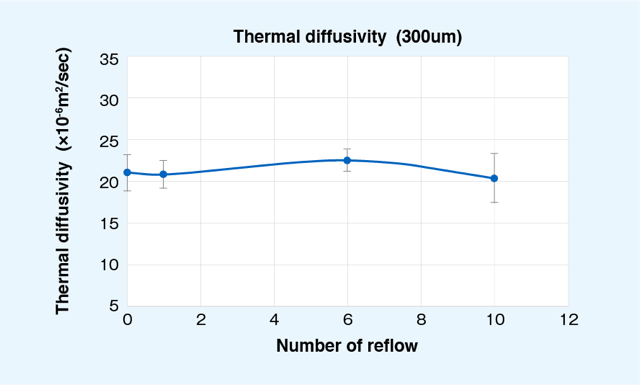

Test condition

- 1Feed the VB200 into the reflow oven at a transfer speed of 0.3 m/min.

- 2During reflow, temperatures were held above 200°C for 1 minute with a maximum temperature of 260°C.

- 3Repeat the reflow up to 10 times on the same sample.

- 4Thermal diffusivity is measured after each reflow.

The thermal diffusivity of VB200 showed almost the same performance as the initial value

after 10 reflow cycles.

- Specialty Materials Sales & Marketing Dept

- +81-3-3216-0590