SDGs Contribution Product Certification Program

The SDGs Contribution Product Certification program is one that serves to certify our products with a particularly high level of contribution to solving social issues as SDGs Contribution Products, helping Zeon Group achieve sustainability. By focusing on the development, manufacturing, and sales of these products, we aim to both contribute to society with sustainable growth as a company, and further promote sustainability management.

Certification Criteria

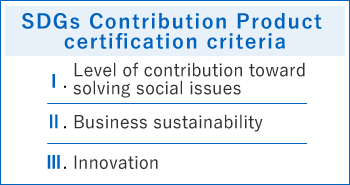

Criteria for certification includes the level of contribution toward solving social issues, the scope of their contribution, and business sustainability. In FY2025, we adjusted the certification criteria to bring them more into line with the program’s goals. The new criteria are: the level of contribution toward solving social issues, business sustainability, and innovation.

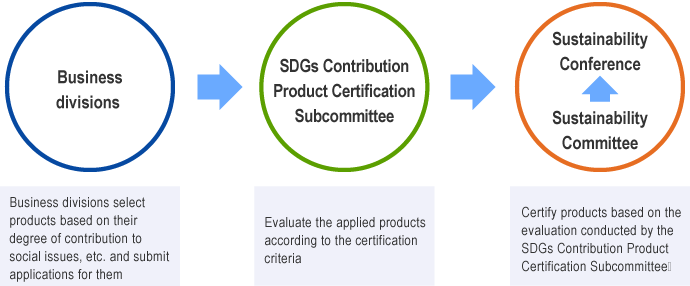

Certification Process

Certification is performed annually. Based on applications made from our business divisions, SDGs Contribution Products undergo a review by the SDGs Contribution Product Certification Subcommittee under the Sustainability Committee, and are then certified by the Sustainability Conference, the company’s highest decision-making body regarding sustainability. Certified products are valid for three years.

Scope Expansion

The scope of certification was expanded in FY2025 to include the products from all Zeon Group companies, not just Zeon Corporation.

Certified SDGs Contribution Products

Besides the 39 products that were certified in FY2024, in FY2025 a further 6 products received certification, bringing the total number of products that have been recognized as SDGs Contribution Product certification to 45.

The products that have received certification include synthetic rubbers such as solution-polymerization styrene-butadiene rubber (S-SBR) and hydrogenated nitrile butadiene rubber (HNBR), as well as Cyclo Olefin Polymers, battery materials (lithium-ion battery binders), polymerized toners, synthetic aroma chemicals, and thermoplastic elastomers. Products that have received certification this year include optical films, RIM formulation and RIM moldings.

Recently, the share of Zeon’s consolidated net sales that these 45 products account for has risen to 38%.

| Products name * Photos illustrating product applications |

Applications and contribution points | Relevant SDGs |

|---|---|---|

Solution-polymerization styrene-butadiene rubber (S-SBR)

|

|

|

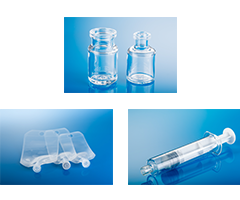

Cyclo Olefin Polymers

|

|

|

Lithium-ion battery binders

|

|

|

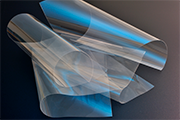

Newly certified products for FY2025Optical film (ZeonorFilm®)

|

|

|

Newly certified products for FY2025RIM formulation and RIM moldings

|

|

|

Future Planning

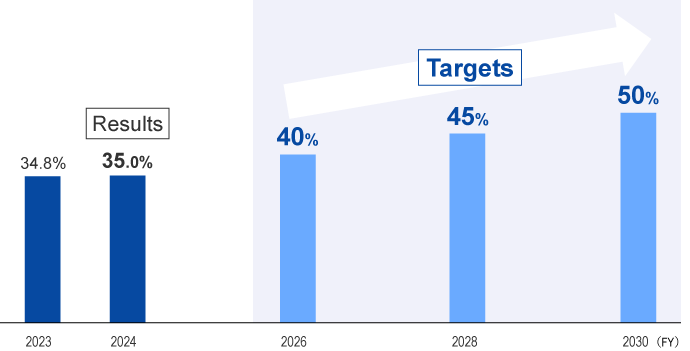

As part of our Medium-Term Business Plan: STAGE30, we have set a target to achieve a 50% sales ratio of products that contribute to SDGs by 2030. In the future, we aim to expand our range of SDGs Contribution Products across the whole Group to achieve the above target.