Occupational Health and Safety / Health and Productivity Management

Basic Approach (Occupational Health and Safety)

Safety Philosophy

A consistently safe work environment is the foundation of all production activities. We formulated our Safety Philosophy in 1997 to guide our safety activities.

- 1Safety is the foundation of all business activities and the greatest priority

- 2Our basic belief regarding safety is that we can prevent all accidents

- 3Safety will be achieved by performing the 5Ss* and when everyone takes responsibility for their own actions

- *5Ss: Seiri (sort), Seiton (straighten), Seisou (scrub), Seiketsu (systematize), and Shitsuke (sustain)

Responsible Care Policy

In 1998, we established our own Responsible Care Policy to define our conduct guidelines based on the Responsible Care. This policy is included in our Environmental and Safety Regulations. We regularly examine the need for revisions to our regulations every three years and as needed.

- 1Prioritize the environment and safety

Protecting the environment and ensuring safety are preconditions for all business activities and are the most important priorities. We will work continuously to enact full accident prevention countermeasures, and provide education and training for all employees to prevent safety and environmental accidents.

- 2Collect and distribute the latest information on chemical products

We will collect, store and manage the latest information required for the appropriate handling, use and disposal of chemical products, and distribute this information to employees and users.

- 3Minimize the discharge of toxic chemicals and waste

We will work to reduce the discharge of hazardous chemical substances, minimize waste, and develop technology for recycling and reusing materials.

- 4Promote activities for conserving resources and energy

We will aim to dramatically reduce the amount of energy we use and help alleviate global warming by developing innovative technology and actively promoting resource and energy conservation activities that involve all employees.

- 5Take the environment and safety into account when developing new processes and products and performing quality assurance

We will perform thorough environmental and safety evaluations from the initial stages of research, develop technology and products that take the environment and safety into account, and work to maintain and improve the quality of technology and products.

- 6Live together with society

We will strictly observe regulations related to the environment and safety, whether the regulations come from the local community, the national government, overseas, or organizations to which we belong. While cooperating in these activities, we will work to enhance our communication with the local community and society in order to convey a better understanding of Zeon’s activities and further strengthen the trust that society has in our company.

- 7Perform continuous improvements

We will continuously improve our environment safety management and technology by operating a Responsible Care Audit, the Safety Management System, an Environment Management System based on ISO 14001, and an Occupational Health and Safety Management System.

Basic Approach (Health and Productivity Management)

In FY2021, Zeon established a Declaration for Health and Productivity Management and Code of Conduct for Well-Being: “For me to be happy” and declared that the company and employees will work together to address health and productivity management. The Declaration for Health and Productivity Management expresses the company’s commitment, while the Code of Conduct for Well-Being: “For me to be happy” incorporates a message and thoughts directed to employees.

The general concept of health and productivity management is that investing in employee health leads to corporate growth, and we believe that implementing health management enables each individual to continue working with enthusiasm and create a truly exciting company. Accordingly, we are focusing our efforts on these initiatives.

In 2023, we established the Health and Productivity Management Conference and focused efforts on proposing and implementing measures from the perspective of employees. Going forward, the company will collaborate with employees to promote health and productivity management.

- Declaration for Health and Productivity Management (October 2021)

-

Our corporate philosophy is “Contributing to the preservation of the Earth and the prosperity of the human race.” This mission will be accomplished by each and every employee of Zeon Group fulfilling his or her potential and playing an active and vibrant role in the company and in the society.

In order for us to continue contributing to a “Sustainable Earth” and a “Safe and Comfortable Lives for People,” we will create a work environment where employees can work cheerfully and vigorously and lead healthy lives, both physically and mentally, with their families and colleagues.

- Code of Conduct for Well-Being: “For me to be happy”

-

- I will be conscious of and proactively work to ensure that I am healthy, happy and empowered in my work

- I will establish the status of my health by means of regular checkups and avail of appropriate feedback and guidance

- I will ask myself if I am sleeping and eating well and maintain awareness of my daily routines, noticing any changes in my condition as soon as possible, and engaging in self-care routines

- I will give due attention to the environment which surrounds me, and make daily improvements to make it safer and more comfortable

- I will understand the resources available around me that will support me in times of emergency

Structure and System (Occupational Health and Safety)

We have built environmental and safety management systems based on the Responsible Care philosophy, and are working toward the goal of ensuring the safety of all persons at our worksites and plants. We have also obtained ISO 14001 external certification related to the environmental field, working on continuous improvement.

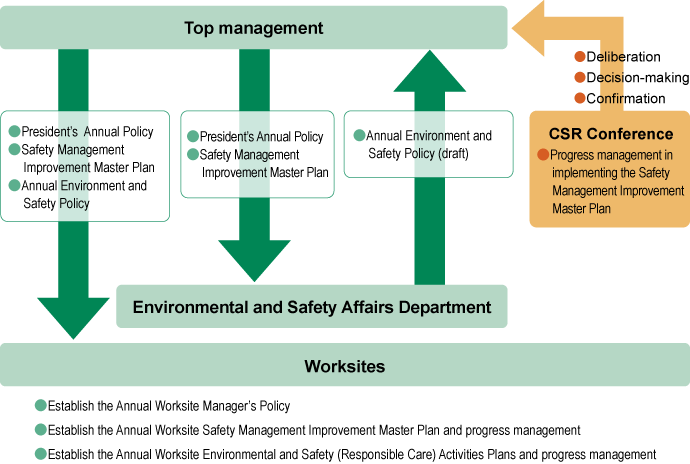

Overview of environmental and safety management systems

- President’s Annual Policy and Safety Management Improvement Master Plan

- These documents are created by top management.

- Annual Environment and Safety Policy

- The General Manager of the Environmental and Safety Affairs Department creates this policy after the President’s Annual Policy and the Safety Management Improvement Master Plan set by top management are released. The Annual Environment and Safety Policy is reviewed by the CSR Conference and finalized by the President.

- Annual Worksite Manager’s Policy and Annual Worksite Safety Management Improvement Master Plan

- Worksite managers create these documents after the President’s Annual Policy and the Safety Management Improvement Master Plan are released.

- Annual Worksite Environmental and Safety (Responsible Care) Activities Plans

- Worksite managers create the Activities Plans after the Group-wide Annual Environment and Safety Policy is released.

Progress management

- Safety Management Improvement Master Plan: Progress verified by the CSR Conference

- Annual Worksite Safety Management Improvement Master Plan: Progress verified by the worksite manager during worksite inspections

- Annual Worksite Environmental and Safety Activities Plans: Progress verified by the worksite manager during worksite inspections

Concrete initiatives for occupational health and safety

Initiatives to prevent occupational accidents and protect the safety and health of all plant employees

We emphasize communication between worksite managers and workers to enhance worksite capabilities while implementing various measures to prevent infectious diseases, with the goal of creating safe, stable production systems. We focus on 5S safety inspections*1, hazard detection*2 activities, and identifying near-miss incidents*3, as well as hands-on safety training.

- *15S safety inspections

Inspections that evaluate operations where safety is an integral part of maintaining the 5Ss (Sort, Straighten, Scrub, Systematize and Sustain), and that are designed to enhance visualization of safety-related issues at worksites and address hazards. - *2Hazard detection (kiken yochi [KY]) activities

Actions taken by workers to analyze and understand unsafe conditions with the aim of recognizing activities that would place them in danger. - *3Near-miss incidents

Events or phenomena that have the potential to result in an accident.

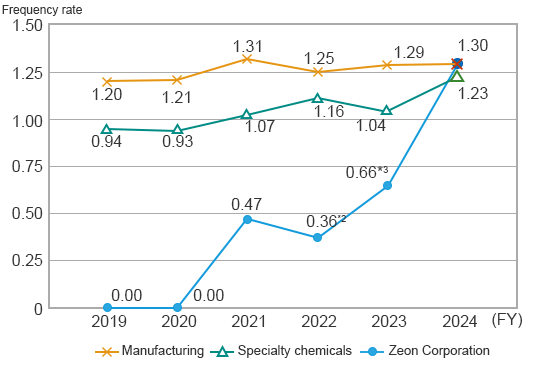

Record of occupational accidents

- *1Lost worktime accident rate

A safety indicator of the frequency of occupational accidents, calculated using the following formula. Frequency of lost worktime accidents = Number of workers who experienced a lost worktime accident / Total working hours × 1,000,000 hours - *2From FY2022, the total value for Zeon Corporation increased to 6 plants from 4 due to an absorption-type merger.

- *3The number of lost worktime accidents increased in FY2024 compared to the previous year.

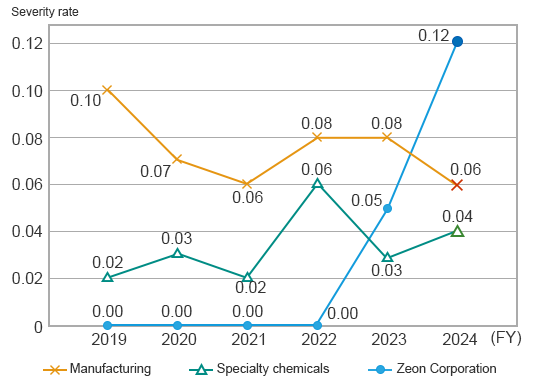

Change in severity rate of lost worktime accidents* (Zeon Corporation)

- *Severity rate of lost worktime accidents = Total number of lost work days / Total actual worked hours × 1,000 hours

5S safety inspections

5S safety inspections assess operations where safety is critical to maintaining the 5Ss (Sort, Straighten, Scrub, Systematize and Sustain). The General Manager of the Environmental and Safety Affairs Department at the head office and Managers at Environmental and Safety Affairs Offices at each worksite conduct patrols of worksites where the Environmental and Safety Affairs Committee is held, to identify areas of excellence and areas where improvements are required (conducted in FY2024 at the Mizushima Plant and the Tsuruga Plant).

Safety and accident prevention

Safety management efforts led by top management

Each year, top management develops the Annual Safety Management Improvement Master Plan and leads initiatives to improve our Safety Management System based on the belief that ensuring safety is the highest priority.

Specifically, we are continuing to conduct priority measures to ensure safety, based on the following straightforward phrases.

- 1Reliable operation of equipment and systems to prevent errors (“Never rely on ‘maybe’ or ‘should’”)

- 2Plant degradation countermeasures and fail-safe measures* (Think smart! Best proposals will be approved.)

- 3Review of past accidents and recurrence prevention (“Never rely on ‘maybe’ or ‘should’”)

- 4Review of standards (“Always follow the rules. Change rules that cannot be followed.”)

- *Fail-safe measures

Modifications to equipment or processes and other measures to prevent accidents that would otherwise result from human error, such as mistakes made by new employees and others lacking in knowledge or experience, or careless mistakes made by experienced employees.

Dialogue between management and plants

To monitor progress on priority issues, Zeon management visit plants on a regular basis to conduct the top diagnosis, hold hearing meetings with employees, and brief them on annual policies. Visits are also made to plants on other occasions to communicate directly with plant employees, who are on the front-line operations. Along with these visits, we concurrently held online meetings from FY2020 to prevent the spread of COVID-19. In FY2024, management made all visits in person, marking a resumption in holding proactive dialogue with worksites over a total of 48 days.

Safety inspector certification at all sites

- Certified Safety Inspector*1

Obtained by Takaoka Plant, Kawasaki Plant, Tokuyama Plant, and Mizushima Plant

- Certified Completion and Process Safety Inspector*2

Obtained by Kawasaki Plant, Mizushima Plant, and Tokuyama Plant

The certification renewal process includes reviews of safety inspection and completion inspection methods as well as inspection management, and verification that our Safety Management System meets the regulatory requirements defined in Japan’s High Pressure Gas Safety Act and that these systems are operating properly.

To more reliably ensure safety at all plants, we employ our Safety Management System, identify the sources of hazards, and implement measures to mitigate risks at all of our plants. We are also formulating our vision for Smart Industrial Safety*3 and promoting initiatives toward the realization of this vision.

- *1Certified Safety Inspector

Certification granted by Japan’s Minister of Economy, Trade and Industry based on the High Pressure Gas Safety Act to allow qualified individuals to perform safety inspections to determine whether specified facilities comply with technical standards, either while the equipment is running or while it is stopped. - *2Certified Completion and Process Safety Inspector

Certification granted by Japan’s Minister of Economy, Trade and Industry based on the High Pressure Gas Safety Act to allow qualified individuals to perform completion inspections to determine whether manufacturing facilities or Class 1 storage facilities that have undergone specific modifications comply with technical standards. - *3Smart Industrial Safety is:

1. An autonomous and independent effort regarding industrial safety by the public and private sectors,

2. From the perspective of appropriate implementation of industrial safety regulations, promotion of industries, and strengthening of competitiveness,

3. In order to deal with economic and social structural changes, including rapid technological innovation, digitalization, low birthrate and aging population, and population decline,

4. Considering the safety of the citizenry and industry as a priority.

Certification status

| Plant | Obtained Certified Safety Inspector status | Obtained Certified Completion and Process Safety Inspector status |

|---|---|---|

| Takaoka Plant | 2000 (renewed in 2020) | - |

| Kawasaki Plant | 1998 (renewed in 2022) | 2008 (renewed in 2022) |

| Tokuyama Plant | 2007 (renewed in 2021) | 2012 (renewed in 2021) |

| Mizushima Plant | 2006 (renewed in 2021) | 2006 (renewed in 2021) |

Occurrences of accidents and injuries

- FY2024: Safety incidents* 9

(High-pressure gas leaks: 2; Other leaks: 4; Smoke: 3)Although these incidents did not result in injury to humans or major impacts on the environment, we set up an accident investigation board for each incident. The boards have investigated the direct and indirect causes of the incidents, and are developing countermeasures to prevent recurrence.

- *Safety incidents

Defined in company regulations as the occurrence of a fire, explosion, leak, damage, failure, runaway reaction, or similar event. Even if there has been no actual occurrence, the possibility of such an event if actions had been delayed and the observation of signs that could be deemed to indicate the potential for such an event are also defined as safety incidents.

Disaster preparedness training

Worksites conduct disaster-response drills each year based on various hypothetical scenarios. The drills include reporting and contracting simulations, first-aid treatment, and rescue and firefighting activities. We conduct full-scale disaster-response drills jointly with local firefighting agencies when possible.

These drills allow us to verify that our standards are adequate, and to verify the operability of emergency equipment (e.g. fire trucks, fire hydrants, broadcasting equipment, etc.). When we encounter problems, we take steps to quickly resolve them, so as to maintain the highest level of disaster-response preparedness.

Third-party evaluations

At Zeon Corporation, we have participated as a supporting company (full member) since the initial establishment of the Japan Safety Competency Center (a specified nonprofit corporation), and have made efforts to evaluate and improve its safety competency in terms of our safety foundation and safety culture. In third-party evaluations, the Japan Industrial Safety Competency Center evaluates our safety foundation. The Keio University format is also incorporated into the evaluation of the safety culture. The strengths and weaknesses of each worksite and department are objectively measured, and we continue to conduct improvement activities aimed at improving our safety competency.

Environmental and safety education

Systematic safety education

Environmental and safety education programs are implemented in accordance with the annual plan set by each worksite.

Group-wide environmental and safety education supervised by the Environmental and Safety Affairs Department is combined with worksite-specific environmental and safety education tailored to the specific needs of each individual worksite.

Shared Group-wide educational content includes content provided through e-learning as well as education on legal amendments of environmental and safety-related laws.

Through these educational activities, we strive to eliminate safety incidents and occupational accidents, minimize damage should an incident or accident occur, and maintain Zeon’s status as an enterprise trusted by local communities.

Manager and supervisor education

Training for newly appointed section managers

This is implemented for newly appointed manufacturing section managers, facilities management section managers, and environmental and safety section managers.

The content of the training includes safety activities based on Zeon’s safety system, safety concerns and responsibilities that safety managers should be familiar with, environmental and safety related laws and environmental and safety related company regulations, and the Safety Management System, etc.

Safety education provided by former plant managers

Education using accident case studies

Held since FY2003, this education program aims to prevent the lessons of past accidents from fading from memory, to apply these lessons in work operations, to raise workers’ awareness of safety, and to increase their sensitivity to potential risks. Former plant managers give presentations to all plant employees. They cover specific examples of accidents at Zeon and other companies to communicate the grim consequences of such accidents, and provide instruction on how to analyze risk factors as well as countermeasures to prevent recurrences. This education is also provided to resident partner companies and Group companies.

Environmental and safety education for new employees

Newly recruited employees at Zeon head office

Presentation of case studies of occupational accidents that have occurred while newly recruited employees were undertaking plant placements, emphasizing the importance of abiding strictly by the rules that have been established in each workplace.

Newly recruited employees at individual worksites

Education in basic matters relating to environmental and safety issues is implemented.

Environmental and safety education and training activities organized by individual worksites

Safety and environmental legislation education

Each individual worksite implements environmental and safety education in accordance with the annual plan (Environmental and Safety Education and Training Plan).

Training activities

Training is implemented in accordance with the annual plan. We strive to improve emergency response capabilities by identifying issues that arise following training implementation and using these to make systematic improvements.

- Comprehensive disaster response drills: These are held once or twice a year, and involve the implementation of disaster response training and evacuation training based on earthquake or tsunami scenarios.

- Individual training: Trainings for the individual self-directed disaster response organization (disaster response teams) and reporting trainings are held.

Educational activities through Safety Workshop

A Safety Workshop has been established at the Mizushima Plant, at which employees can acquire practical experience in the various types of safety rules. In accordance with the “Standards Governing Usage of the Mizushima Plant Safety Workshop,” initiatives are conducted using the “Plant Safety Rules Understanding Verification Sheet” to check employees’ level of understanding of safety rules; in addition, initiatives are held that make use of education based on the exhibits in the Safety Workshop to promote understanding of plant rules among plant personnel (including the personnel of partner companies).

Adoption of hands-on safety education

Safety experiential education is conducted at plants, research facilities, resident partner companies and neighboring Zeon Group companies. Every year experiential education is provided on accidents in which employees are caught or trapped by machinery, electrostatic explosions and burns, shocks from residual pressure in couplers, accidents involving objects falling, and accidents involving cuts.

In the future, we will continue to implement this type of education systematically, including repeated training.

Safety-related risk assessments

Hazard detection (kiken yochi) activities

4R-KY (four-round kiken yochi) activities

4R-KY is a hazard detection method where employees analyze and understand their work tasks before starting them, to avoid placing themselves in danger. The process is carried out in four separate rounds.

KY trainers assigned to each workplace lead these activities.

Identifying near-miss incidents

Near-miss incidents are events that have the potential to result in a major accident, injury or loss. The concept of near-miss incidents comes from Heinrich’s Law, which suggests that in a workplace, for every accident that causes a major injury, there are 29 accidents that cause minor injuries and 300 incidents that cause no injuries (near misses). By collecting and sharing data on potentially serious near-miss incidents, we will strive to prevent the occurrence of major accidents.

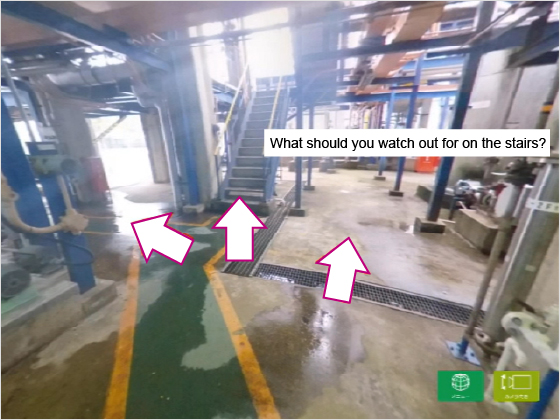

In FY2024, focusing on the fall accidents that occurred frequently in FY2023, we analyzed near-miss incidents of falls at the Takaoka Plant, Kawasaki Plant, Mizushima Plant, Himi Futagami Plant, and Tsuruga Plant, and conducted dialogues involving the worksite of each plant.

Improving plant safety

We conduct Plant Safety Evaluations and Plant Safety Inspections to further raise the level of safety at plants and prevent serious accidents and injuries from occurring.

Plant Safety Evaluations (assessments of new lines)

We verify plant safety at the design stage when commissioning a new plant or upgrading an existing one.

Plant Safety Inspections

For existing plants, while inspecting work areas, we ensure that all sources of danger have been identified and review past decisions regarding the need for safety measures.

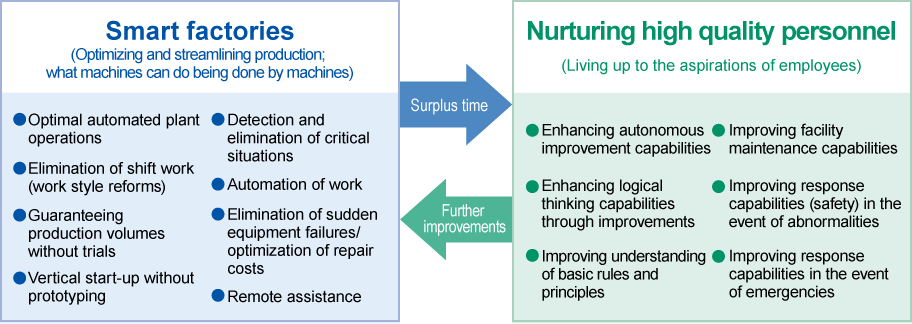

Creation of “smart factories” to simultaneously improve plant efficiency and realize work style reforms

At Zeon, we have been working to make our plants “smarter” since 2020. We have already carried out various activities to facilitate production innovation (visualization and utilization of intangible assets, including know-how and expertise of skilled and experienced workers) to date. The creation of smart factories will enable further production innovations and transformations in work tasks by increasing the range of things that can be accomplished by machines through the leveraging of digital technologies. For plants, this will lead to optimized and streamlined production while continually ensuring product quality. For employees, it will lead to the realization of comfortable and rewarding work environments.

As part of the “Smart Factory Realization Project” undertaken throughout Zeon Group, we initially discussed the “Vision of an Ideal Plant” in six areas (work operations, safety, quality assurance, facilities, personnel, and logistics and warehousing), establishing the specifics of what we hoped to achieve via the creation of smart factories, as well as the steps needed to achieve this. Meanwhile, it is important to organize these various ideas and initiatives to facilitate optimization of the whole, rather than groupings of digitization initiatives partially optimized for individual fields.

Initiatives undertaken over a two-year period as part of this project involved pilot tests ranging from studies on ways to achieve the transition to smart factories to those on optimizing the whole, thereby identifying the topics to be addressed. We also worked out the organizational structures and a visualization of the digital human resources which would be required to achieve these goals. Since April 2022, initiatives to facilitate the creation of smart factories are being continued by the Production Innovation Center based on the Medium-Term Business Plan.

Example 1: Reduction of essential tasks through transition to the use of robotics

Activities for production innovation have to date reduced on-site troubleshooting operations by around 90%. We have now reached a juncture of considering whether to further reduce essential tasks required for production to reduce workloads even more. In this context, we deliberated on the potential of adopting digital technologies intended to reduce essential tasks.

If plant patrols can be replaced with cameras and robots, this would allow the time thus saved by increases in efficiency to be used for other improvement activities (workstyle reforms), while also improving operator safety. In addition, standardization of work tasks and the development of facilities for the transition to the use of robotics would further facilitate improvements in the basic infrastructure of plants.

As a result of conducting reviews inside actual plants, it was found that commercially available functions would not meet our implementation needs, and the technical issues that need to be resolved to have robots move around automatically were identified. The direction for solving these issues is becoming clear as we are accumulating expertise through investigations conducted in collaboration among industry, government, and academia while combining various peripheral technologies and solutions. Our objective remains to realize safer work environments where people are not placed in dangerous situations during emergencies.

Example 2: Mechanisms for achieving both safety and quality

We have formalized the know-how of veteran operators and introduced and used an intelligent production system*1 that enables less experienced operators to also perform safe and stable operations.

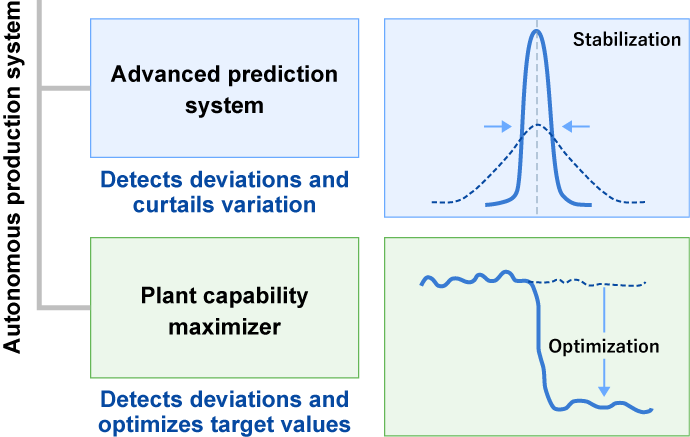

To advance this system even further, we are investigating the introduction of an autonomous production system*2 that will make high-level forecasts and predictions on factors that can lead to quality changes, and based on those forecasts and predictions, support operations with optimized quality and costs by integrating the formalized know-how with data science.

- *1, 2DAICEL Production Innovation method

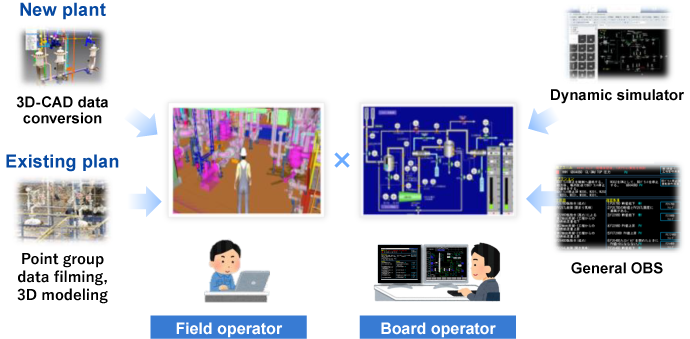

Example 3: Immersive training using VR technology

To operate a plant, it is important to acquire the ability to respond in the event of abnormal conditions, in addition to understanding basic rules and principles. The introduction of VR technology during training drills is expected to facilitate improvements in the efficiency of both instructors and those under their instruction by allowing them to repeatedly be exposed to various situations and facilitate autonomous learning.

To raise the efficiency of new employee training by using virtual reality, we have looked into the use of 360-degree cameras. It creates an environment where learners can move freely throughout the plant in a virtual space and learn procedures by performing them repeatedly without the need to go to the actual work site. As a result of our investigations, we were able to perform all photography, document preparation, and revisions in-house and we have now started use in practical training.

Training for more advanced troubleshooting drills, and launching new plants is under ongoing consideration as the burden involved in creating training materials is high.

Structure and System (Health and Productivity Management)

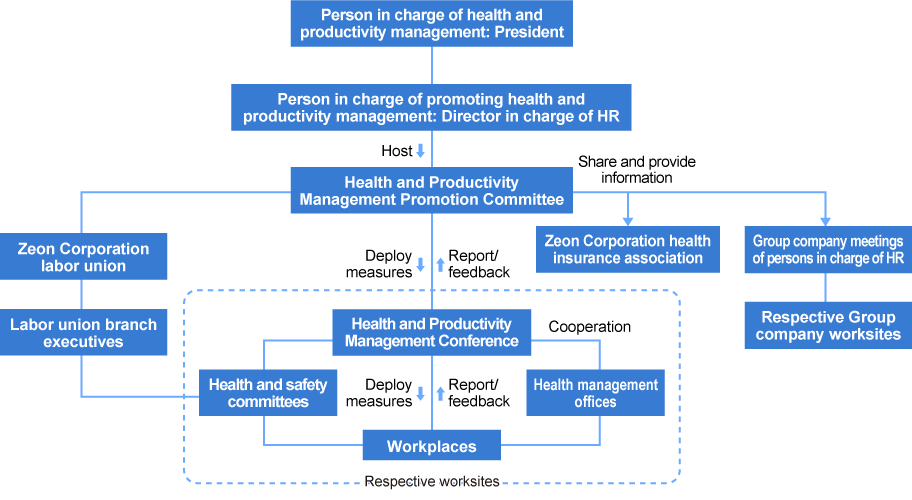

The President and CEO is positioned as the person in charge of health and productivity management.

The Health and Productivity Management Promotion Committee is chaired by the director in charge of human resources with participation from representatives of the labor union. The Committee both deliberates on measures and makes decisions on health and productivity management.

We established the Health and Productivity Management Conference as its subsidiary organization in FY2023. It conducts activities to establish health and productivity management initiatives among employees through sharing worksites’ independent initiatives and building a cooperative structure between the head office and worksites.

Key Initiatives

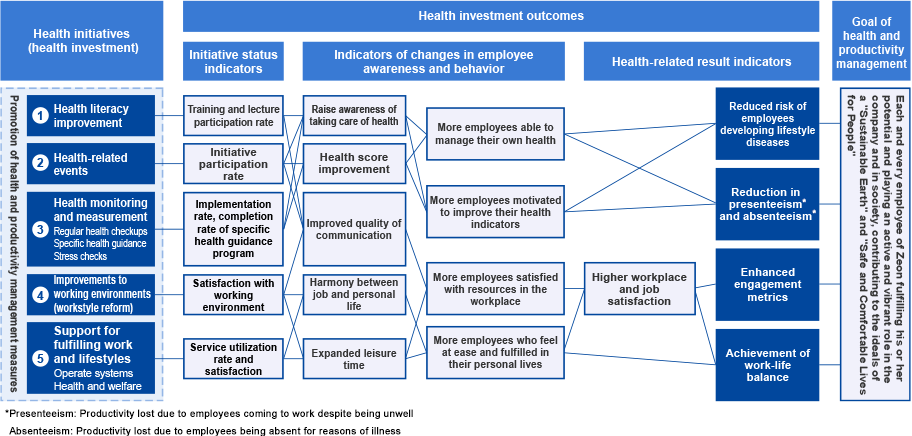

Health and productivity management targets and key issues/policies (Health and Productivity Management Strategy Map)

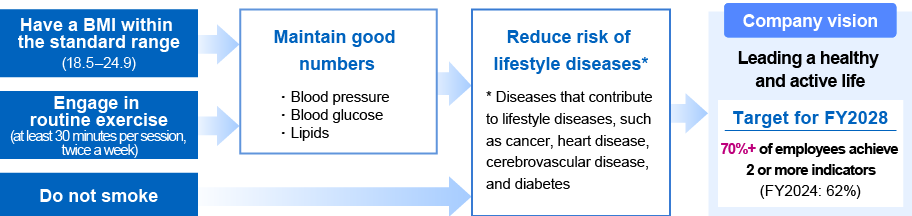

Introducing Zeon Healthy Behavior Indicator

In Phase 2 of STAGE30, our Medium-Term Business Plan that we launched in FY2023, we created the Zeon Healthy Behavior Indicator to set forth our goals for physical health. This original index consists of the three health indicators of a BMI within the standard range, engaging in routine exercise, and not smoking. Key points of this index were making the self-assessment easy to complete and including healthy activities that anyone can do. We have set the target of increasing the percentage of employees that satisfy two or three of the three health indicators from 60% (FY2022) to 70% (FY2028) and are taking steps to achieve this target.

Physical and mental health initiatives

Mental health training

We distribute video content on mental health for all employees. In addition, the Line Care Training for line positions, with our company-employed psychiatrist serving as the instructor, provides training with content based on familiar examples.

Health checkups and follow-up care

For regular health checkups, industrial physicians and nurses provide follow-up consultations and health guidance for persons who require guidance. We have also launched a system that allows employees to view their health checkup results online 24 hours a day, with the intent to provide a state of health awareness whenever it is convenient. Awareness of health is the first step to creating good health. We will cultivate awareness for health through the launch of this system.

Stress checks

We conduct annual stress checks every July. Feedback is provided to employees at worksites and activities to improve workplace environments are conducted.

Launch of support for external counseling

We have launched support for external counseling with the aim of promoting better mental health and well-being. Professional counselors provide support for resolving work-related problems, health worries, and other issues.

Independent worksite initiatives

We implement measures to promote health tailored to the specific issues and needs of respective worksites, including walking events, physical fitness measurements, and the adoption of menus with healthy food options at cafeterias, as well as the holding of seminars to improve health literacy.

Flexible work styles initiatives

We are promoting the maintenance of “environments to facilitate flexible work styles unconstrained by time and place,” which includes the extension of teleworking and the flex-time system, as well as by making it possible to take annual paid leave in hourly increments, as means to encourage the realization of well-being for each and every employee.

Office environment improvement

Prompted by the increased permeation of teleworking, we reviewed the role of the office, defining it as “a confluence point for communication to collaborate and cocreate as well as for education.” Employing a unilateral open-plan layout encompassing all organizational units and departments, as well as introducing state-of-the-art ICT infrastructure to facilitate flexible work styles, head office has transformed itself into a stage on which all employees can be active. From FY2024, to strengthen organizational capabilities by taking the best of both teleworking and in-office work, we are further expanding office functions and changing layouts to foster communication among employees when they come to the office.

While improving the environment for flexible work styles, we are also advancing initiatives that reaffirm the value of face-to-face interaction, such as group work aimed at casual communication and programs that encourage connections among employees and departments.

Deregulation of dress codes

At head office, we have deregulated dress codes with the aim of creating a work environment where each and every employee can freely express their own ideas and conduct themselves with autonomy.

Enhanced support for transferees

We have expanded and enhanced our support for transferred employees to reduce burdens at the time of transfer and to cover expenses for traveling home. If an employee returns to their pre-transfer home or if a spouse joins the employee at the new assignment, the company pays travel expenses according to distance zones separate from the unaccompanied transferred employee allowance. We also began paying expenses for travel home for some single employees if they are transferred to a business location other than the area where they were initially hired. We expect that these enhanced support programs for transferred employees will help all our employees to thrive and work with enthusiasm.

Launch of side work system

We have introduced a side work system. This system is being used to support employees to realize their career aspirations, by allowing them to build their careers by gaining skills and experience through side work and pursue self-realization by taking on challenges they seek out themselves.

Initiatives to reduce overtime work and promote taking of annual paid leave

As part of various measures to realize freedom and well-being, we are working to reduce overtime work and promote the taking of annual paid leave.

To reduce overtime work, we have implemented measures such as working days within regular hours (instituted days with no overtime) and a review of operating staffing levels at plants, resulting in a downward trend in recent years.

To raise the rate of employees taking annual paid leave, we have also made it easier to take leave, such as by setting up days and periods of time where taking annual paid leave is encouraged and creating programs to enable taking leave in single-hour and half-day increments. As a result, the rate in 2024 reached 75.6%, achieving the 2026 target of 70% ahead of schedule for the second consecutive year.

Initiative to expand application of the teleworking system

To realize work styles not tied to a particular place, we are conducting a trial expansion of the teleworking system at some worksites to allow employees to work at places apart from the standard telework locations (employees’ homes and shared offices). While the majority of participants in the trial have given positive feedback, including the ability to have flexibility in how they work and more fulfillment in private life, employees providing nursing care support have also requested an increase in the maximum number of days they can use the program. In response to this feedback, in FY2024 we maintained the number of days the program can be used at 40 work days, making the system easier to use. Aiming to create a teleworking system that supports employees in balancing their work and private life, we will continue to conduct measures while listening to employee feedback.

Supporting employees with children by creating leave programs

Approximately 80% of married union member households have both partners working, and as a result, it is necessary for the company to create an environment where employees can continue their careers with confidence even if their spouse is transferred. Employees who are recognized as having difficulty continuing to work due to accompanying a spouse who is being transferred to another location are allowed to take a leave of absence for up to three years. The objective of this program is to avoid disrupting the careers of employees confirmed through discussions with the labor union and to prevent the loss of high-quality human resources.

Health and welfare service: Zeon Cafeteria Plan

We have introduced the Zeon Cafeteria Plan, a system which allows employees to make their own choices from a menu of options to support the “peace of mind” and “career development,” as well as options to help them “connect/co-create.”

It can be used for various purposes, including health promotion, encompassing comprehensive physical examinations and fitness clubs; support for childcare and nursing care, including babysitting and daycare services; self-development activities, for example correspondence courses and language study; to avail of facilities for overnight stays; and travel expenses for employees on assignment without their family, as well as for those using nursing care, to return to their family home.

GLTD Program (Zeon Corporation Long-Term Rehabilitation Support Program)

We established this program with the aim of supporting creation of conditions that allow employees and their families to live with peace of mind. In the event of an illness or injury that prevents someone from working for a long period, this program compensates the employee at the company’s expense for a portion of the employee’s income for as long as up to their 65th birthday. Employees can also enroll in an optional plan that increases this compensation and attach a rider that covers unpaid periods during caregiving leave.

Establishment of Childcare Leave Consultation Service

We have established the Childcare Leave Consultation Service as part of our efforts to improve understanding of the systems for childcare leave and to create an environment conducive to availing of this leave, while supporting the taking of childcare leave as well as offering support to those returning to work.

We are also working to create a comfortable work environment for employees with childcare responsibilities by, for example, expanding eligibility for leave to care for sick children and exemptions from overtime for those providing childcare.

Expansion of nursing care support

With the aim of helping employees to balance the obligations of their job and nursing care, we have established an external nursing care consultation service.

Employees can consult nursing care specialists about issues or concerns they have by email or over the phone, with the service acting as a safety net for nursing care consultations.

In addition, we have published a nursing care support handbook to give employees basic information on nursing care. Going forward, we plan to actively disseminate information and conduct training to entrench the system.

Expansion of support leave

Toward the consolidation of an environment in which they can work in peace of mind, we have established a system making it possible for employees to avail of paid support leave in the event that it becomes difficult for them to work due to personal injury or illness, or other unforeseen situations such as closure of schools of their children after they have taken all of their allocated annual paid leave for the year.

| Work styles unconstrained by time and place | ★Flex-time system, ★teleworking system, ★overhaul of head office, ★deregulation of head office dress code, encouraging the taking of annual paid leave, half-day holidays, ★taking of annual paid leave in hourly increments (some worksites), instituted days with no overtime, ★elimination of postings of employees at locations remote from their families (some worksites), and ★launch of side work system |

|---|---|

| Maternity/childcare support systems | Maternity leave before and after birth, ★childcare leave and childcare leave at birth (up to five days paid leave) system, ★childbirth leave for spouses (for male employees), leave to care for sick children or to deal with other related situations, half-day leave, shortened working hours system, limits on overtime work, exemptions from late night work, child nursing time, childcare/caregiver leave financial support system, childbirth cash payments, dependents allowance, tuition allowance, ★support leave, flextime system with no defined core times, ★cafeteria plan, and development of guidelines for taking childcare leave |

| Nursing care support systems | Nursing care leave, caregiving leave system, consultation service for nursing care, ★development of a nursing care support handbook, and ★cafeteria plan |

| Support for health improvement | Regular health checkups, ★launch of health checkup results viewing system, stress checks, ★employee engagement surveys, physical fitness measurements, mental health training, ★seminars on women’s health issues, issuance of health news, ★holding of events to support health, ★cafeteria plan, and ★COVID-19 (some worksites)/influenza workplace vaccination program |

| Asset accumulation | Employee savings scheme, employee stock ownership scheme (with financial incentives), defined-contribution (DC) corporate pensions, and matching contributions system |

| Housing assistance | Housing assistance system (dormitory accommodation and company housing, rent subsidy system, home ownership allowance, and home rental for transferred employees) |

| Systems for holidays and absences | Annual paid leave (up to 22 days granted), ★support leave system (up to 40 days granted), menstrual leave, childbirth leave, job transfer leave, relocation leave, public-service leave (for jury duty), disaster leave, quarantine and infectious disease leave, paid leave for family births, marriages or bereavement, ★childbirth leave for spouses, My Life leave (on reaching the age of 50), leave to care for sick children or to deal with other related situations, nursing care leave, volunteering leave, leave for hospital visits by expectant mothers, refreshment leave (for senior employees), and ★leave of absence due to spouse’s job transfer |

| Self-help | Disaster assistance, group medical insurance, compensation for absences from work (Zeon health insurance cooperative association), optional group insurance, group medical insurance, and ★GLTD system |

- ★: Initiatives expanded during the period of the Medium-Term Business Plan (FY2021–FY2024)

Harassment prevention measures

In our Zeon Group Human Rights Policy, established in 2019, we declared our commitment to respect for human rights and not tolerating acts of discrimination or harassment. We have also established the Zeon Group policy on harassment prevention and the harassment prevention rules.

Based on these policies and rules, we have established a harassment consultation service which accepts consultations regarding acts of harassment, suspected cases, and concerns. Furthermore, we provide harassment training for employees in management positions and regularly issue awareness-raising news on harassment to ensure harassment prevention throughout the company.