Resource Circulation and Pollution Prevention

Basic Approach

Environmental philosophy

Established in 2001, our Environmental Philosophy guides our efforts to deliver products with consistent quality through safe and reliable production while reducing our environmental impacts.

- 1Environmental protection is a mission of a socially responsible organization

- 2Our basic belief is that environmental protection can be achieved with innovative technology

- 3Environmental protection will be achieved when all employees work together with a sense of mission to overcome challenges

Structure and System

We have built environmental and safety management systems based on the Responsible Care philosophy, and are working toward the goal of ensuring the safety of all persons at our worksites and plants. We have also obtained ISO 14001 external certification related to the environment.

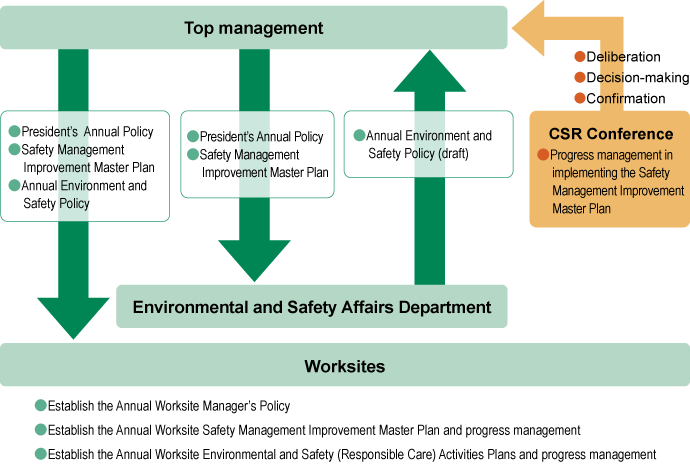

Overview of environmental and safety management systems

The management systems are operated through hierarchical policies and plans as outlined below.

- President’s Annual Policy and Safety Management Improvement Master Plan

- These documents are created by top management.

- Annual Environment and Safety Policy

- The General Manager of the Environmental and Safety Affairs Department creates this policy after the President’s Annual Policy and the Safety Management Improvement Master Plan are released. The Annual Environment and Safety Policy is reviewed by the CSR Conference and finalized by the President.

- Annual Worksite Manager’s Policy and Annual Worksite Safety Management Improvement Master Plan

- Worksite managers create these documents after the President’s Annual Policy and the Safety Management Improvement Master Plan are released.

- Annual Worksite Environmental and Safety (Responsible Care) Activities Plans

- Worksite managers create the Activities Plans after the Group-wide Annual Environment and Safety Policy is released.

Progress management

The progress of each policy and plan is verified and managed under the structure outlined below.

- Safety Management Improvement Master Plan: Progress verified by the CSR Conference

- Annual Worksite Safety Management Improvement Master Plan: Progress verified by the worksite manager during worksite inspections

- Annual Worksite Environmental and Safety Activities Plans: Progress verified by the worksite manager during worksite inspections

Key Initiatives

Chemical substances management

PRTR* initiatives

We are implementing Group-wide initiatives to reduce release and transfer of substances subject to Japan’s PRTR Act.

- *PRTR: Pollutant Release and Transfer Register

Air, water, and waste materials

Atmospheric emission reductions of hazardous chemical substances

We are installing collection facilities, implementing measures including improving facilities to prevent evaporation from openings in manufacturing facilities, and systematically reducing emissions of butadiene and acrylonitrile, which are among the substances requiring priority action under the Japan’s Air Pollution Control Act.

Initiatives to prevent air and water pollution

Our emissions of NOx and SOx, which are air pollutants, occur during the combustion of fuels such as BC heavy oil.

Each worksite complies with regulatory limits under pollution-related laws and regulations and with voluntary management standards, striving to curb emissions in daily operations.

We are also promoting measures such as the adoption of heavy oil with low sulfur (S) content and conversion to liquid natural gas (LNG).

Going forward, we will proceed with technical and economic assessments toward converting to fuels with lower environmental impact, aiming for even lower emission levels.

In managing the quality of our plant wastewater, we comply with the standards of the Water Pollution Prevention Act and agreements with local authorities (voluntary management standards) and work to ensure appropriate water quality conservation.

Waste reductions

As part of our efforts to reduce the amount of industrial waste destined for final landfill disposal, our worksites achieved the standard of less than 0.1% of the industrial waste generated in FY2007, realizing zero emissions in FY2011. Since then, we have maintained that status.

Zeon Group companies also had a final landfill volume of more than 600 tons in FY2007, but since FY2012 this has been reduced to around 10 tons, or roughly 0.4% of the industrial waste generated in FY2007. This is considered zero emissions.

The Group companies will aim to maintain a final landfill volume of 5 tons or less per year, the same as at our worksites.

Initiatives to reduce industrial waste from plastic products

Article three in our Responsible Care Policy is “Minimize the discharge of toxic chemicals and waste.”

Under the Act on Promotion of Resource Circulation for Plastics, which came into force in April 2022, Zeon is classified as a business that generates a large amount of industrial waste from plastic products (250 tons or more per year). In line with the spirit of the Act, we are working to reduce the amount of waste we generate, while also formulating medium- to long-term targets and plans to manage waste.

Chemical product safety information

We collect and provide safety information on our chemical products. We also conduct hazard assessments.

For quality assurance, see Quality Management.

Information for the proper handling of chemical products

We produce Safety Data Sheets (SDS) providing information including GHS*1 classification results, product hazards, and cautions for handling, etc.

For some of our products, we also compile safety-related information in the form of safety abstracts, which are made available on the GPS/JIPS*2 platform.

- *1GHS

Globally Harmonized System of Classification and Labelling of Chemicals - *2GPS/JIPS

Global Product Strategy / Japan Initiative of Product Stewardship. An industry voluntary initiative promoted by the Japan Chemical Industry Association, based on the fundamental concept of the global initiative by the International Council of Chemical Associations (ICCA)

Participation in voluntary chemical industry initiatives

Zeon provides financial support for research activities by the LRI*1 to assist in efforts such as chemical substance hazard reviews, safety evaluations, and environmental impact surveys. Zeon also participates in the Technology Subcommittee and the Environment Subcommittee of the Asia Pacific Section of the IISRP*2. In international meetings, Zeon proactively participates in activities to improve the overall level of technology in the global rubber industry and to promote sustainability

- *1LRI

Long-range Research Initiative: Activities to provide long-term support for research on the impact of chemical substances on health and the environment. A program under the auspices of the International Council of Chemical Associations (ICCA) that is carried out with funding from LRI member companies and in cooperation with the chemical industries of Japan, the United States and Europe (specifically, the Japan Chemical Industry Association, American Chemistry Council and European Chemical Industry Council). - *2IISRP

International Institute of Synthetic Rubber Producers