Environmental Management

Basic Approach

Environmental Philosophy

Established in 2001, our Environmental Philosophy guides our efforts to deliver products with consistent quality through safe and reliable production while reducing our environmental impacts.

- 1Environmental protection is a mission of a socially responsible organization

- 2Our basic belief is that environmental protection can be achieved with innovative technology

- 3Environmental protection will be achieved when all employees work together with a sense of mission to overcome challenges

Structure and System

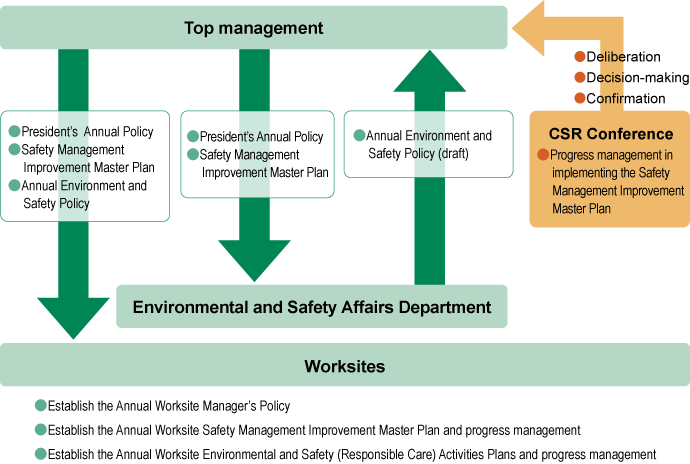

We have built environmental and safety management systems based on the Responsible Care philosophy, and are working toward the goal of ensuring the safety of all persons at our worksites and plants. In the environmental field, we have also obtained ISO 14001 external certification and are working on continuous improvement.

Overview of environmental and safety management systems

- President’s Annual Policy and Safety Management Improvement Master Plan

- These documents are created by top management.

- Annual Environment and Safety Policy

- The General Manager of the Environmental and Safety Affairs Department creates this policy after the President’s Annual Policy and the Safety Management Improvement Master Plan set by top management are released. The Annual Environment and Safety Policy is reviewed by the CSR Conference and finalized by the President.

- Annual Worksite Manager’s Policy and Annual Worksite Safety Management Improvement Master Plan

- Worksite managers create these documents after the President’s Annual Policy and the Safety Management Improvement Master Plan are released. The Annual Worksite Manager’s Policy is intended for all workers at the worksite, including our employees and partner company staff.

- Annual Worksite Environmental and Safety (Responsible Care) Activities Plans

- Worksite managers create the Activities Plans after the Group-wide Annual Environment and Safety Policy is released.

Progress management

- Safety Management Improvement Master Plan: Progress verified by the CSR Conference

- Annual Worksite Safety Management Improvement Master Plan: Progress verified by the worksite manager during worksite inspections

- Annual Worksite Environmental and Safety Activities Plans: Progress verified by the worksite manager during worksite inspections

Key Initiatives

Audits (assessments of existing lines)

Audits assess whether our management systems are functioning normally.

In particular, worksite Responsible Care audits cover environmental and safety initiatives and are headed by the General Manager of the Environmental and Safety Affairs Department. These audits have two parts: the Responsible Care Audit and the Responsible Care Dialogue.

Responsible Care Audits

- Audits using specialized indicators to monitor the progress of Responsible Care activities

- These audits also cover worksites that have Certified Completion and Process Safety Inspectors for High-Pressure Gas

- The progress of improvements in areas where audits uncovered such needs is verified using the Audit Findings Improvement Plan and Progress Report

Responsible Care Dialogues

- A venue for dialogue among worksite members and management to jointly consider, discuss, and find solutions to worksite environmental and safety issues that are difficult to identify through audits

Responsible Care Audits at Group companies

Group Company Responsible Care Audits cover Group company Responsible Care activities and are headed by General Manager of the Environmental and Safety Affairs Department. The progress of improvements in areas where audits uncovered such needs is verified using the Audit Findings Improvement Plan and Progress Report.

Internal plant audits

Internal plant audits are conducted at plants as outlined below.

- Plant manager inspections: Inspections of the progress of Responsible Care implementation conducted by the plant manager (at least once/year)

- Environmental Management System (EMS) internal audits, and Safety Management System internal audits

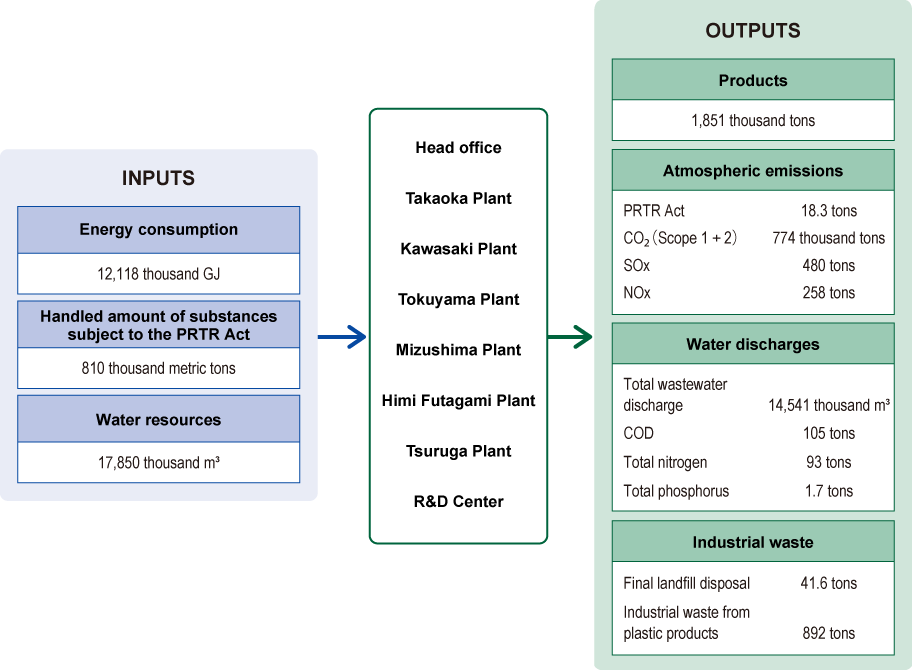

Overview of environmental impacts

We procure raw materials for chemical substances, and consume energy and water resources in the production and sales of our materials and chemical products. In manufacturing products, at the input (resources introduced) stage, we evaluate resource and energy efficiency while also ensuring quality.

Regarding outputs (emissions), while emitting substances that have environmental impacts on water and the atmosphere may be unavoidable, we are implementing ongoing improvements to minimize these emissions.