ZeonorFilm®

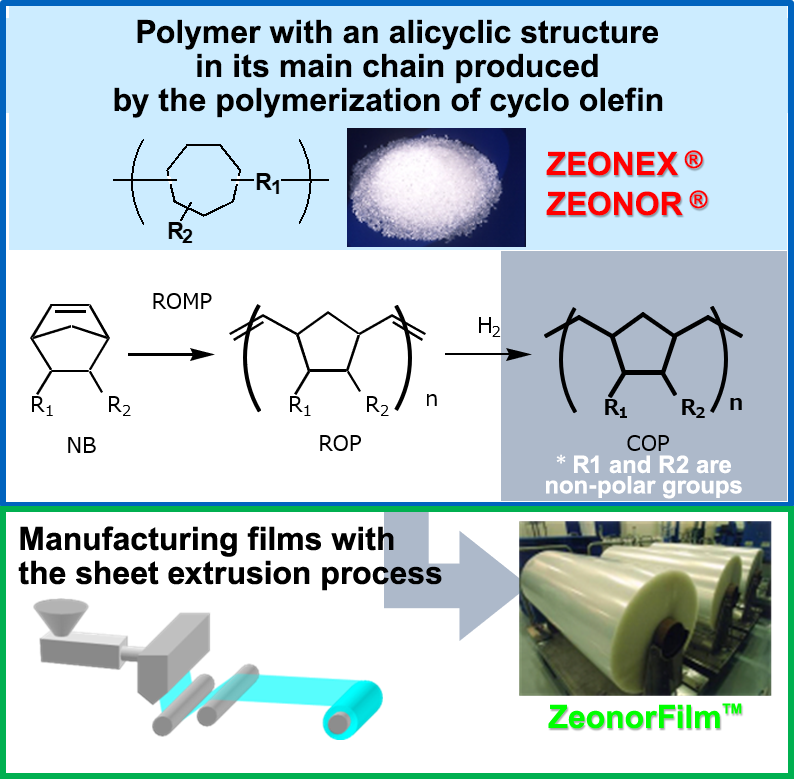

ZeonorFilm® is a plastic film formed by sheet extrusion using ZEONOR® cyclo olefin polymers (COP) produced by Zeon as a raw material.

It has been described as a plastic that comes closest to glass in terms of properties such as low water absorbency and low moisture permeability, which typical plastics do not exhibit.

The excellent optical stability that comes from Zeon's proprietary precision processing technology makes it useful for a broad range of applications, including displays.

Characteristics

| Characteristics | Details |

|---|---|

| High transparency | High transparency encompassing the short wavelength range |

| Low birefringence | Very little change in optical properties associated with factors such as stress while using ZeonorFilm® |

| Low water absorbency and low moisture permeability | The low water absorbency and low moisture permeability properties of COP used as a raw material of ZeonorFilm® are maintained in the end product. These effectively ensure the product's optical and dimensional properties in high-humidity environments . |

| High heat resistance | Offers excellent durability under high glass transition temperatures (Tg). |

| Low amount of out-gassing and high purity | Very low out-gassing or impurity due to the use of highly pure raw materials and the application of sheet extrusion for the film manufacturing process. |

| Low dialectic constant | Low dielectric constant and low dialectic tangent , which minimizes transmission loss and deterioration in transmitting electric signals. |

| Chemical resistance | The COP used for ZeonorFilm® demonstrates resistance to polar solvents, acids, and alkaline chemicals. On the other hand, it exhibits weakness against ether- and hydrocarbon-based chemicals. Please contact us to confirm product resistance to specific chemicals. Zeon also has products with enhanced chemical resistance for your consideration. |

| Low adsorption (protein) | The COP used for ZeonorFilm® demonstrates low adsorption of proteins. This property has been successfully applied in the field of medical analysis in the form of products such as cells and microplates for blood analysis. |

| Micro-processing/Releasability/Transferring property | ZeonorFilm® is a material capable of nano-level micro-processing and also offers an excellent transferring property and releasability. In addition, it is suitable for thermal and ultraviolet (UV) imprinting. |

ZeonorFilm®

ZeonorFilm® is available in a variety of types according to the differences in processing methods.The glass transition temperature (Tg) of the raw material ranges from approximately 120°C to 170°C.

Product Lineup

Products can be processed into various types of film using Zeon's proprietary processing method.

| Processing Method | Series | Characteristics |

|---|---|---|

| Extrusion | ZF | Film produced by extrusion |

| MD stretching | ZM | Film produced by uniaxially stretching in the direction of production flow |

| TD stretching | ZT | Film produced by uniaxially stretching in the direction of product width |

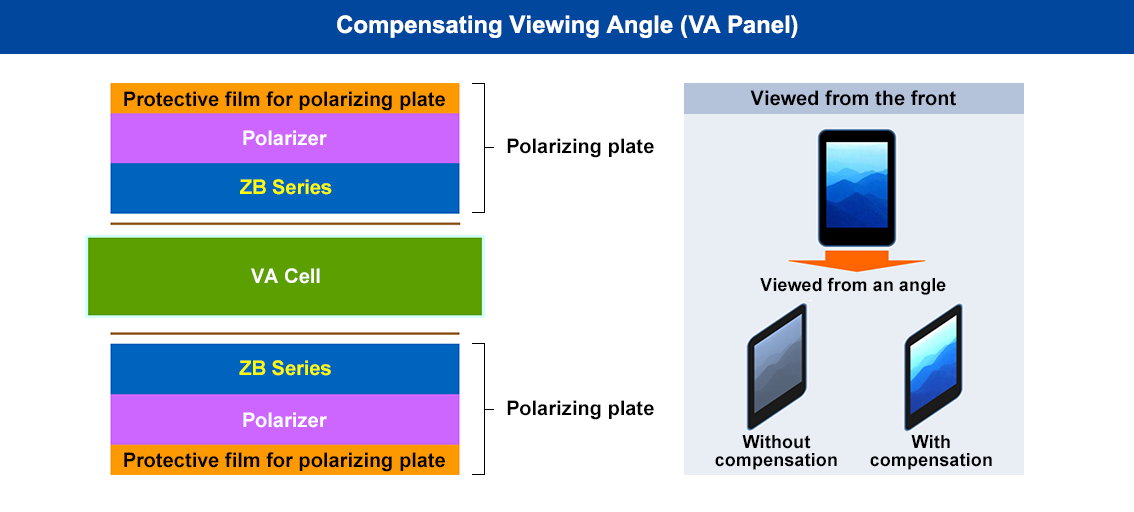

| Biaxial stretching | ZB | Film produced by extrusion and sequential biaxial stretching |

| Unique stretching | ZD | Film produced by diagonally stretching the orientation axis |

Retardation Film for Displays

Product is widely used in conventional flat panel displays.

ZeonorFilm® is an essential component of polarizing plates used in LCD and OLED devices.

Examples of applications for ZeonorFilm® in flat panel displays

(Configuration Examples)

- In the configuration for LCD devices, liquid crystal is sandwiched between polarizing plates.

- ZeonorFilm® is positioned on the side of these plates facing liquid crystal cells.

- Enhances visibility when viewing the device from a slanted angle.

- Without the retardation film, the image will appear with a white hue that makes viewing difficult.

Film for Enhancing the Visibility of Displays

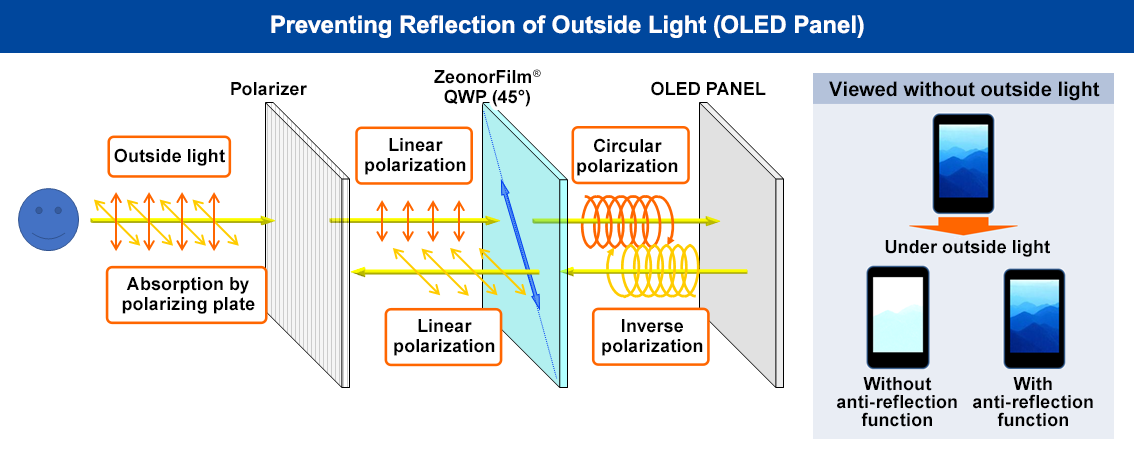

- Have you ever experienced difficulty viewing your smartphone or tablet display when you are outdoors due to reflected sunlight or another light source?

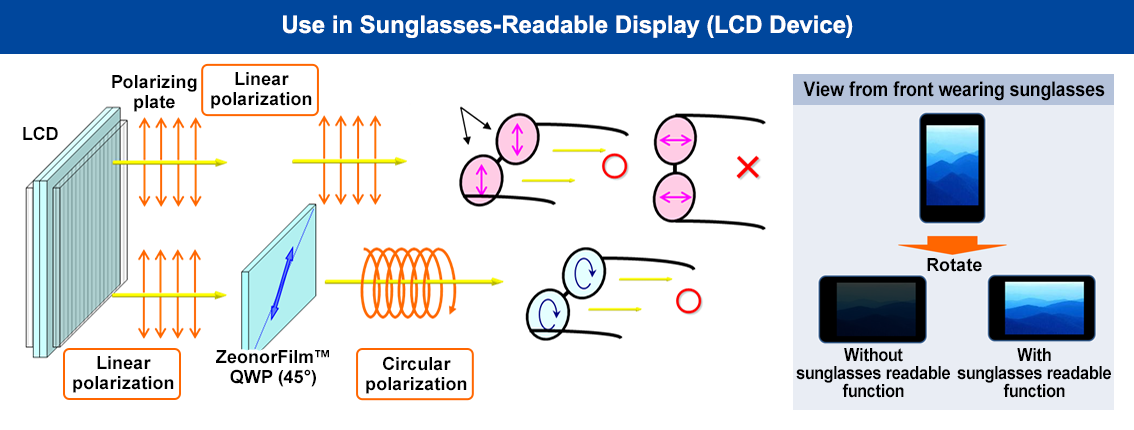

- Have you experienced a display appearing black, with little or no visibility when viewed through sunglasses?

ZeonorFilm® can solve these problems.

(Mechanism and Functions)

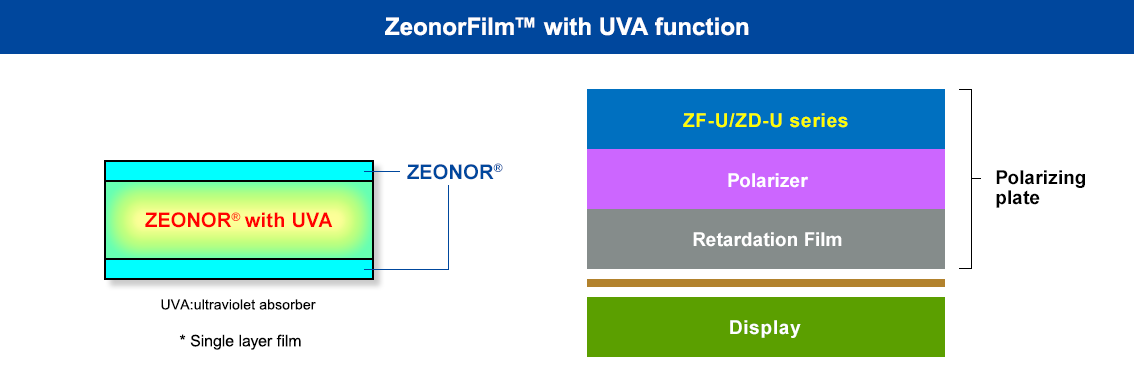

ZeonorFilm® with UVA function

ZeonorFilm® with UVA function used as protective film for polarizing plates

(Configuration Examples)

- The product is used as the protective surface of polarizing plates (requires surface processing)

- to block ultraviolet light, which can damage devices internally.

For related materials, please contact us at the address below.

- Specialty Components Div.

- +81-3-3216-1793